Babcock – one of Britain’s foremost complex naval systems suppliers – will fit its weapons handling launch system (WHLS) onto the South Korean Navy’s (SKN) Jangbogo III-class conventional diesel electric attack submarines.

Designated the KSS-III project, the Jangbogo III-class, also known as Dosan Ahn Chang-ho class, is a series of next-generation diesel-electric attack submarines being built to strengthen the naval defence capabilities of the South Korean Navy.

KSS-III involves the development of nine boats being built in three batches as part of South Korea’s indigenous submarine production programme.

Batch II will include three submarines, with some design changes from the Batch I hulls. The remaining three submarines will form Batch III and feature even more advanced technologies.

A Batch II submarine will feature an overall displacement of 3,600 tonnes. It will have a total length of 89 metres (m) and width of 9.6m.

Over the next decade, the estimated contract allocation of Batch II boats will cost more than $2bn, according to the leading intelligence consultancy GlobalData.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData

Babcock’s patented air turbine pump on Batch II submarines

Babcock has worked with Hanwha Ocean on the programme since 2011; the supplier is currently halfway through delivering hardware for Boat 4.

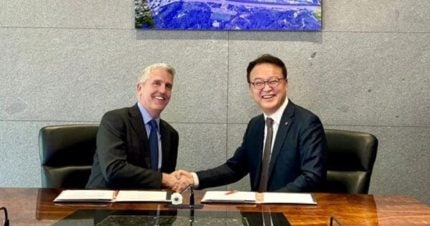

Under a seven-year contract, South Korea’s prime contractor Hanwha Ocean will continue to utilise the UK company’s expertise in furnishing the class with the WHLS, starting with Boat 6.

Boat 6 of the class – or the third boat of Batch II – along with the rest of the class, will make use of Babcock’s air turbine pump and programmable firing valve launch system.

Key elements of the WHLS will be designed and produced in the UK with the remainder built under licence in South Korea.

“In an increasingly complex geopolitical climate, defence customers want products and services which are affordable, capable and available,” Neil Misell, chief executive for Babcock Mission Systems. “Babcock’s air turbine pump system successfully satisfies these requirements and our team’s top quality reputation is reflected by its delivery of all major Jangbogo-III milestones on time or early.”

“In an increasingly complex geopolitical climate, defence customers want products and services which are affordable, capable and available.”

Neil Misell, chief executive of Babcock Mission Systems.

Misell refers to Babcock’s previous work on the programme in which it fulfilled 217 milestones either early or on time.

WHLS is Babcock’s patented air turbine pump solution that discharges torpedoes, mines and missiles from a launching tube. The company notes that this proprietary system is compact and efficient as it uses less firing air, meaning the system is quiet and has lower maintenance requirements than other handling and launch systems.

Besides South Korea, Babcock has also designed, manufactured, and provided in-service support for submarine WHLSs for more than 50 years – with products currently used by the UK, Spanish, South Korean and Canadian navies.