The US Navy's USS Independence (LCS 2) has successfully completed the first selected restricted availability works at Southwest Regional Maintenance Centre (SWRMC) in San Diego, California.

SWRMC supervised the work conducted on the LCS 2 under its major contractor, General Dynamics National Steel and Shipbuilding Company (NASSCO).

USS Independence project officer lieutenant Shawn Williams said: “USS Independence met all scheduled milestones. SWRMC and NASSCO were able to support the ship's damage control material assessment (DCMA) and light off assessment (LOA) on time.”

The primary works required dry-docking of the USS Independence included AMAH hull strengthening, waterjet anode pocket and stern tube replacement, as well as replacement of several 10in overboard discharge valve and 12in suction valves.

Other efforts included air-conditioning plant accumulation tank modification, mission bay stanchion strengthening, and Number 1 and 2 ship service diesel generator (SSDG) top-end overhauls.

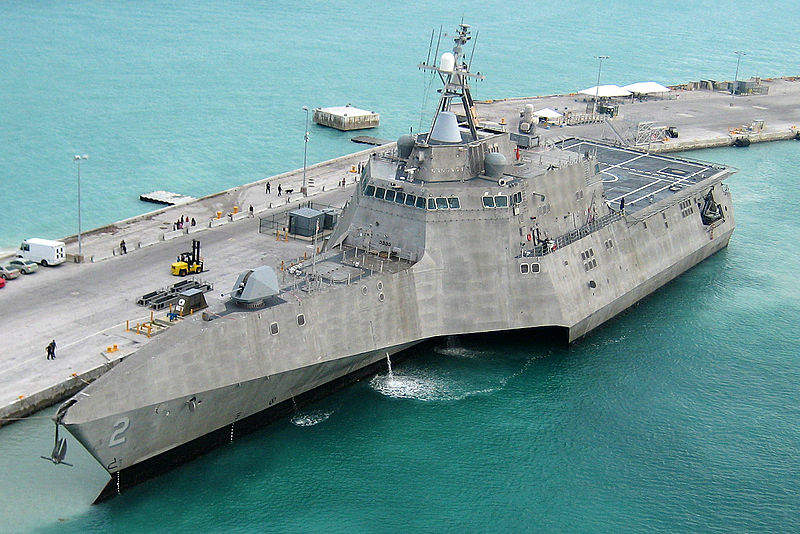

The LCS is being built in two variants, with the Freedom type being built and delivered by Lockheed Martin and the Independence type by Austal.

The LCS is designed to perform missions that include countering littoral mine threats, diesel submarine threats, and surface threats, such as small surface craft attacks.

Designed based on a trimaran hull, USS Independence (LCS 2) was launched in April 2008 and commissioned in January 2010.

Image: Littoral combat ship USS Independence (LCS-2). Photo: courtesy of US Navy air crewman 2nd class Nicholas Kontodiakos.