The Hameln Class (Type 333) minesweepers were built for the German Navy by an industrial consortium led by STN Systemtechnik Nord (comprising STN Atlas Elektronik, Abeking & Rasmussen, and Fr. Lurssen Werft), which later built the Frankenthal Class minehunters. The twelve Hameln minesweepers were commissioned between 1989 and 1991. The Hameln Class minesweepers and Frankenthal Class minehunters have the same basic ship design and engineering systems but have different mission specific equipment suites. The Hameln was fitted with conventional mechanical and influence mine sweeping and minelaying capability. Political and strategic changes during the early 1990s brought about a reduction in the importance of fast minelaying and the Hameln ships have been modified to become minesweepers and minehunters and control ships for Remotely Operated Solenoid Sweepdrones (ROSS) which are remotely operated magnetic and acoustic sweeps.

DESIGN

The German Ministry of Defence and the shipbuilding industry investigated the performance of non-magnetisable steel, wood and glass reinforced plastics (GRP) materials for the ships’ hulls. The non-magnetisable steel was selected for performance, whole life cost, and mature proven shipbuilding processes. The ship structure is able to meet all minewarfare roles, including surveillance, minelaying, minehunting and minesweeping.

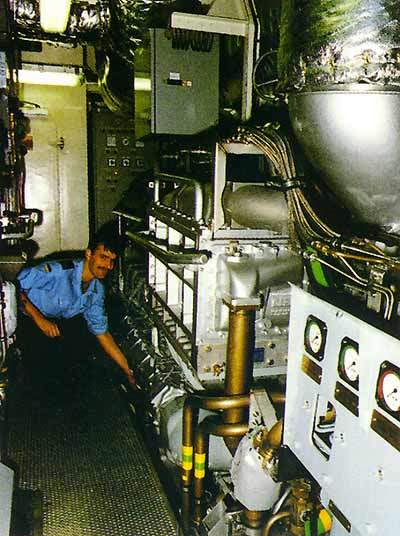

In order to minimise noise emission from the hull, the ship’s equipment has been installed on low-frequency, vibration-resilient mountings. The engine components are mounted on an intermediate concrete block with double elastic bearings. The concrete block acts as a counterweight providing vibration attenuation.

WEAPONS

The minesweeper is equipped with two four-cell Stinger missile launchers. The Stinger FIM-92 missile provides short-range defence against low flying aircraft. The missile was developed by Hughes Missile Systems (now Raytheon), and has been manufactured under licence by EADS.

MINE DISPOSAL VEHICLES

The ships are equipped with one-way Seawolf and Seafox mine disposal vehicles from the Naval Division of Atlas Elektronik. Seafox and Seawolf are single-shot mine disposal vehicles, Seawolf being the larger and heavier version. Seawolf is armed with a larger explosive charge than Seafox for the detonation of large buried mines. Seafox and Seawolf are non-recovery lightweight self-propelled ammunition, equipped with sonar for automatic homing and also a fibre-optic link for operation from the ship. A live television camera and halogenic headlights allow positive identification of the target prior to detonation.

COUNTERMEASURES

The Hameln minesweeper is equipped with the DR 2000 radar warning receiver from Thales (formerly Thomson-CSF). The receiver detects pulse and continuous wave radars. The signal processing system characterises radar emissions in terms of frequency, pulse repetition rate, pulse width, amplitude and bearing, and compares the data with a threat library to identify the threat radar.

Two Silver Dog rocket launchers for chaff decoys are installed. The KMW Silver Dog is a very lightweight system and has low magnetic and low acoustic signature. The system is manually operated and not integrated with the radar warning equipment.

SENSORS

The ship has the Thales Nederland (formerly Signaal) WM/20/2 surface search radar operating in I and J bands. The navigation radar is the SPS-64 I-band radar from Raytheon.

The ships are being upgraded with the installation of the hull-mounted DSQS-11M sonar from Atlas Elektronik. The DSQS-11M was designed either as part of the ATLAS MWS80-4 Mine Countermeasures system as installed on the Frankenthal Minehunter Type 332, or for autonomous operation as on the Type 343 Minesweepers. The system uses pulse compression and other advanced signal processing techniques to provide computer-aided detection, classification and tracking of mines and mine-like targets. For route surveys the operator can select side-scan mode.

PROPULSION

The ship has two MTU 16V 538 TB91 diesel engines, each providing 2200kW, with two shafts driving variable pitch propellers. The engines provide a speed of 18 knots.

The engine control equipment installed in the Engine Control Room consists of eleven computers linked via a data bus.