The Huon design is based on the Italian Gaeta/Lerici Class. Six minehunters have been built by ADI in Newcastle, Australia and operate from the HMAS Waterhen naval base in Sydney. The first of class, HMAS Huon (82), entered service in 1999. Other vessels are Hawkesbury (83), commissioned February 2000, Norman (84), commissioned August 2000, Gasgoyne (85), commissioned June 2001, Diamantina (86), commissioned May 2002, and Yarra (87), commissioned March 2003.

COMMAND AND CONTROL

The command system integrates the tactical data system with the major platform and operational systems. It includes the following features: control and operation of the suite of sensors and weapons; control of the main and auxiliary propulsion systems; and integrated control of all internal and external communications, including the transfer of messages and mine countermeasures data from the tactical consoles. The Integrated Ship Communications System has been developed by CEA Technologies.

The system allows the management of all mine countermeasures activities, including mission planning, minehunting, mine disposal and post mission analysis. Where ship manoeuvring during minehunting operations is being automatically controlled, the system controls the auxiliary propulsion system via the minehunter autopilot. This provides the ship with auto-track and auto-hover for effective mine countermeasures operations.

GUN

Main gun is a DS 30B 30mm gun from MSI Defence Systems, which has a firing rate of 650 rounds/min and ranges of 3km anti-air and 10km anti-surface.

MINE COUNTERMEASURES

The ships are equipped with two Bofors SUTEC Double Eagle II mine disposal vehicles. The vehicles are electrically powered and are equipped with a search light, closed-circuit low light television camera, and onboard detection and identification sonar. The vehicle’s tether cable contains a fibre-optic link for transmitting command signals from the ship and relaying sensor images for display on the multi-function consoles in the ship’s operations room. A DAMDIC mine disposal charge from Nordic Defence Systems is slung beneath the vehicle for release in close proximity to the mine. The mine disposal charge is detonated via a thin wire link running from the ship. The vehicle can be deployed at distances of more than 500m from the ship. Clearance divers are carried on board the disposal vehicles and are capable of diving to 90m. The ships are being fitted with the new remotely activated Cormorant Lift Bag which brings mines to the surface for disposal.

The vessels have the ADI Oropesa Double “O” mechanical sweep and can also tow the ADI Mini Dyad influence sweep. The ships are being fitted with the new ADI Australian Acoustic Generator (AAG) minesweeping system. AAG is a water-driven, turbine-powered sweep, which is programmed to emulate the acoustic signatures of specific classes of ships. The ship is also capable of towing the ADI Dyad magnetic acoustic influence sweep.

The ship is also fitted with a BAE Systems Australia Prism III ESM system and two ML Aviation SuperBarricade chaff launchers.

SENSORS

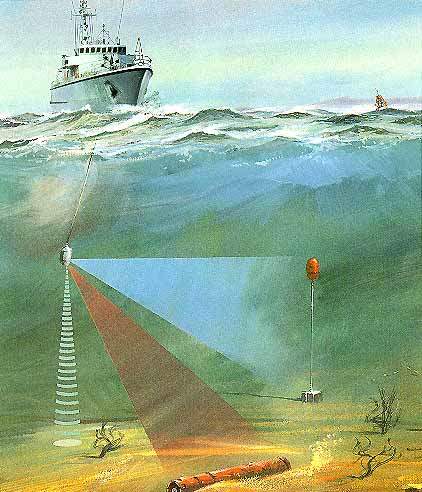

The Type 2093 minehunting sonar from Thales Underwater Systems (formerly Thomson Marconi Sonar) is a variable depth sonar which can be operated in the hull-mounted mode or in variable depth mode. The sonar has dual-frequency search and classification capability. In the variable depth mode both frequencies operate simultaneously, the lower frequency covering mid-water to surface depths and the higher frequency covering the seabed. The sonar uses frequencies typically 30 to 100kHz for detection and 300 to 500kHz for classification. The system achieves a detection range greater than 1000m and a classification range greater than 200m.

Thales Underwater Systems is developing the Acoustic Mine Imaging (AMI) system for use in turbid waters. This active, high-frequency sonar is 3D imaging and determines the range, bearing and elevation of mines. It is to be deployed from the Double Eagle mine disposal vehicle.

Navigation radar is the Kelvin Hughes Type 1007 I-band radar.

PROPULSION

The main propulsion consists of a 1460kW Fincantieri GMT diesel driving one shaft controllable pitch propeller. The auxilliary propulsion system consists of three 124kW electro-hydraulic motors driving Riva Calzoni retractable auxiliary propulsion units or thrusters, one forward and two aft. The thrusters have sufficient power to sustain the ship speed at a constant 6 knots.