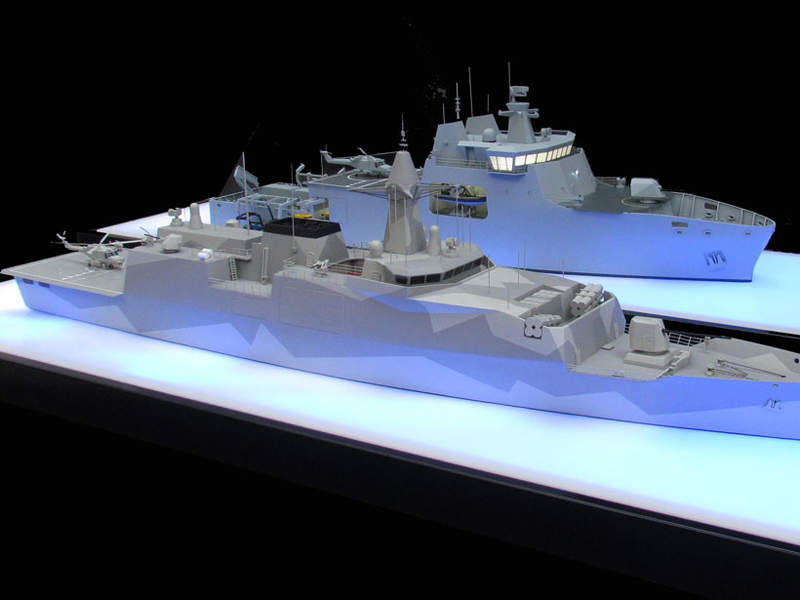

The VENARI-85 mine warfare and hydrographic ship is being developed by UK-based BMT Defence Services for use by navies to meet current and future mine warfare needs.

The ship can perform various missions, including mine countermeasures (MCM), anti-submarine warfare (ASW), maritime security, humanitarian assistance and disaster relief, and hydrographic survey.

The ship’s concept design was introduced at the Defence and Security Equipment International (DSEI) exhibition held in September 2017.

VENARI-85 mine warfare and hydrographic ship design and features

The 85.9m-long mine warfare and hydrographic ship will be capable of carrying 500t of payload. Its hull form will be optimised to provide high manoeuvrability and positional accuracy in a wide range of sea conditions at different locations.

The on-board aviation facilities, including flight deck and hangar, are intended to support unmanned and manned aircraft operations. Located at the stern, the flight deck can support take-off and landing operations of a single AW159 Wildcat multi-role helicopter.

The mission equipment garage will be located at the aft to store a variety of equipment and systems, including autonomous unmanned vehicles (AUVs), tethered remotely operated vehicles (ROVs), Atlas Elektronik SeaFox mine disposal vehicle, and other mission-specific vehicles for use in MCM and maritime security roles.

The spacious working deck at the aft will house unmanned surface vehicles (USVs), such as Atlas Elektronik ARCIMS for hydrographic survey duties. It can also accommodate large containers to carry additional equipment and stores. The ship will use a pair of rigid hull inflatable boats to conduct naval interdiction and inspection operations.

The launch and recovery of the unmanned systems will be performed using motion-compensated davits from multiple positions with a high level of redundancy. A telescopic gantry davit at the stern will be used to transport large containers weighing up to 25t and to support humanitarian assistance and disaster relief operations at sea and ports.

The ship will also feature replenishment at sea (RAS) facilities to replenish fuel, equipment and stores, as well as an integral medical facility with a decompression chamber for rescue operations.

Command and control

The VENARI-85 ship’s operations will be controlled from a large tactical bridge located amidships. The open architecture and modular design of the bridge will allow the command team to manage mine warfare operations from the bridge, mission system workspace or garage.

Armament of VENARI-85

The mine warfare vessel can be armed with a 30mm main cannon for self-defence in coastal mine warfare operations. It can be fitted with a 40mm cannon or a 57mm medium-calibre gun with an all-weather fire control system to perform expeditionary mine warfare missions.

The vessel can also be installed with two additional remotely operated guns and small calibre cannons to provide increased protection against surface threats.

A soft-kill decoy system can also be fitted for defence against air, surface and sub-surface targets.

Sensors

The ship can be integrated with a variety of mission-specific sensors, including surveillance radar, navigation systems, variable depth sonar (VDS) and towed array sonar (TAS) systems, antennas, and radio communications.

The surveillance radar will be used to detect incoming threats and provide command and control.

A hull-mounted mine avoidance sonar can be installed to provide underwater surveillance and safety for crew members.

Survivability of VENARI-85

The ship will also feature low-radar signatures, while the 3D degaussing equipment on board will further increase survivability by making the ship invisible to a magnetic field.

The on-board shock protection system will offer protection for personnel and mission systems from the impact of a mine explosion.

VENARI-85 propulsion

The VENARI-85 mine warfare ship will integrate a fully redundant diesel-electric propulsion system, including four diesel generators and two electric motors. The generators will drive a pair of propellers through conventional shafts.

The propulsion system will also feature twin rudders and lateral tunnel thrusters for high manoeuvrability.

A DP2 class dynamic positioning system will also be fitted to maintain the ship’s position at sea.