TechPrecision Corporation, through its US and Asian subsidiaries, partners with its customers to provide cost-effective solutions for fabricated and machined metal products, components and systems. Our primary markets are defense and aerospace, power generation (nuclear, solar, wind, and hydro), cleantech, commercial and chemical processing, and medical devices. We also provide solutions for other high-tech markets such as national laboratories, research and development, and rapid prototyping.

Large-scale precision manufacturing for the defense industry

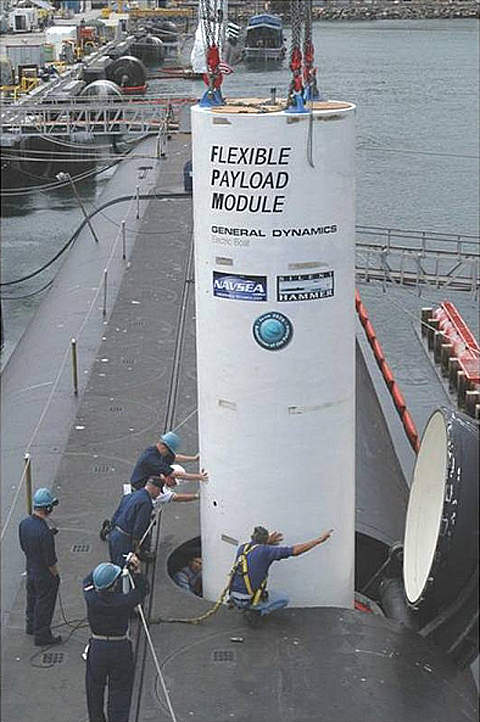

We are an ISO 9001:2008 registered company, and our certifications include ASME stamps (S, PP, U, N, R, NPT, NA and NS) MIL-Q, MIL-I, MIL-STD and NAVSEA. Our defense experience includes weapons systems, propulsion systems, fuel tank domes and bulkheads, sonar array housings, submarine components, missile tubes, large tanks and pressure vessels, and various test and mounting fixtures. We treat all our defense work with the highest level of security and priority, and we are ITAR registered and regulations compliant.

Large-scale precision manufacturing engineering, fabrication, machining and assembly services

For more than 50 years, TechPrecision and its subsidiaries have provided precision, large-scale manufacturing engineering, fabrication, machining and assembly / testing services that exceed our customers’ tight design tolerances and specifications. With our manufacturing know-how, experience and insights we deliver end-to-end, global manufacturing solutions that can save you time and cost without compromising the quality of your final product.

We are a public company (OTC: TPCS) and financially sound. For further information about the company, please visit our website. You will find links to our subsidiary companies there as well.

Fabricating and machining services for the defense industry

Ranor was founded in 1956 in Fitchburg, MA. Ranor’s reputation for fabricating and machining demanding components, delivered on-time, quickly spread. The customer base soon expanded to include OEMs in the steam turbine, paper-making and machine tool industries.

In 1975, Ranor moved to its present location in Westminster, MA. Situated on 65 acres in north central Massachusetts, our 160,000ft² manufacturing facility is the home to state-of-the-art equipment unique to our industry.

We’ve earned our reputation through outstanding technical expertise, flawless attention to detail, total comment to quality, and excellence in customer service. We’re proud to offer our customers a ‘one-stop shop’ for complete products requiring not only fabricating and machining, but also ancillary services such as material processing, heat treatment, painting, blasting, and testing.

Ranor project management methodologies are based on best practices and lessons learned from more than 50 years of experience in the manufacture of sophisticated, precise metal fabrications. These methods ensure systematic management of project scope, schedule, cost and quality to provide our customers with the highest value service and product.

Large-scale metal fabrication and machining

Wuxi Critical Mechanical Components was formed in 2010 as a wholly foreign owned enterprise (WFOE) to meet the growing global demand for large-scale metal fabrication and machining. Our customers indicated interest in expanding business with TechPrecision if we could support them locally in Asia, and we moved quickly to meet this demand.

The formation of this WFOE was based on the significant growth in demand for solar and nuclear energy components in Asia – especially China. We have been successful with this strategy by leveraging the expertise at our US facility to scale-up our Asian facilities, all while accelerating manufacturing technology transfer to adequately address future demands within Asia. By adding this capability to the TechPrecision organization, we are able to deliver increased capacity and lower cost solutions to our growing global customer base.