With expertise in providing specialised solutions, SAB Bröckskes has been a leader in cable manufacturing for decades. Its know-how, gained from experience in a variety of industries, is included in each and every product it supplies. Now, the medium-sized family owned company is presenting a new product line for shipbuilding.

The development of the new BlueLine cable series has been advanced in co-operation with customers in the shipbuilding field. The new cables are available as halogen-free SABIX BlueLine cables or as high-temperature and oil-resistant type BlueLine TA 180 C.

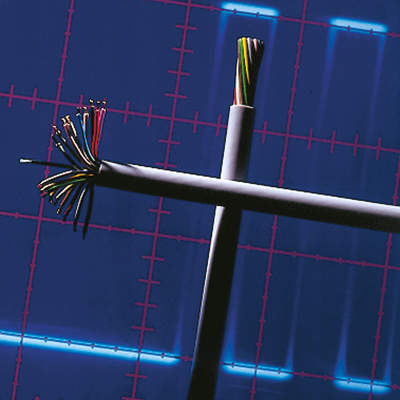

All SAB Bröckskes BlueLine types are constructed with tinned copper strands in class 5 to offer advantages in corrosion resistance and flexibility.

Halogen-free marine cables for the shipbuilding industry

Halogen-free SABIX BlueLine cables have been approved by Germanischer Lloyd (GL), LR and ABS. SABIX characteristics fulfil the highest safety-related aspects in shipbuilding with regards to fire performance, as well as being halogen-free.

Data cables, type SABIX BlueLine Data, are available with small cross sections, starting at 0.14mm² (AWG 26). This results in a small outer diameter, which offers an outstanding advantage particularly where there is limited space available; for example, during the installation and wiring of navigation and bridge electronics such as BNWAS.

SABIX BlueLine Control and SABIX BlueLine Power complement the new product series with control and power supply cables for electrical components.

Temperature, oil and fuel-resistant marine cables

The BlueLine TA 180 C type cable has been developed for application in areas with extreme environmental influences. The screened control cable with fluorine plastic insulation is designed for use in control panels for ship diesel engines. It is suitable for adverse conditions in engine rooms, even under extreme ambient temperatures. As well as being both oil and fuel resistant, the cable has impressive chemical resistance.

As well as an excellent fire performance and rugged construction, the BlueLine TA 180 C type convinces with very high flexibility and exceptional handling during installation. With approval from GL, it also offers a certain planning reliability for classification.

Flexible, recyclable cable technology

SABEX has several outstanding characteristics. As registered trademark of SAB BRÖCKSES GmbH & Co KG, it combines progressive cable technology with highest security for the user.

Standard halogen-free cables offer a large degree of safety to humans, nature, buildings and machinery, but have a large disadvantage: they are often too inflexible to compete with PVC in applications.

However, this is not the case with SABIX. SABIX possesses several technical advantages compared with PVC.

The outstanding characteristics of the SABIX include (material types depending on the modifications):

- Oil resistant according to DIN-VDE and EN

- Flexible at low temperatures up to -40°C

- Heat resistant up to 90°C

- Suitable for outdoor application

- Extremely flexible

- Impressive capacitance values

- Increased abrasion resistance

- Fully recyclable

- Low smoke density according to DIN-VDE, IEC, BS and EN

- Flame retardant and self-extinguishing according to DIN VDE, IEC and EN

- Halogen-free according to DIN-VDE and IEC

When used correctly, there is no health risk associated with SABIX. The product line is completely recyclable and can be reused after decomposition.

Research and development into marine cables

Solid results are neither influenced by luck or chance but by years of experience, ingenious techniques, technical competence, as well as the ability to develop the new, and test and improve the existing.

In order to meet the challenge of today’s and future market developments successfully, our innovative endeavours are of the greatest importance. We are continuously engaged in new and further development of our products in order to complete our cable range and to extend and strengthen our market position.

We are manufacturing the best quality products for the market supported by intensive development, research and testing. New products are the result of close communication between customers, sales and development departments, laboratories and raw material suppliers.

SAB Bröckskes disposes of all testing methods required by the VDE, as well as those of numerous international approvals. In addition, we use many other testing devices, such as our reversed bending machine for extreme strength and long-term testing.

We guarantee the quality of our products, resulting in our customers and final users having confidence in the solutions we supply.

SAB: We go forward

Founded in 1947, SAB is a leading manufacturer of cables worldwide. More than 60 years of experience in temperature measurement and control technique, as well as in cable production, have turned a one-man business into a company with nearly 500 employees.

Our strength is not only the production of standard products but also the development and manufacturing of special products according to customers’ specifications. Every year we manufacture more than 1,500 special products at our customer’s request. Every single product is a challenge for our technical team. At Bröckskes, we see ourselves as the manufacturer and service provider, in the sense of a real partnership and customer-oriented work.

The quality of our products is known in more than 40 countries worldwide. Our customers have tested our products intensively and confirm that they have a longer service life than others. In all product ranges, we are certified according to DIN EN ISO 9001:2008. Our future slogan is “We go forward”.