FEROFORM and RAILKO are advanced engineering composite materials, exclusively manufactured by TENMAT, and are widely recognised as the industry standard for demanding applications such as stern tube, propeller, A-bracket and rudder bearings, steering gear, deck equipment, offshore and bitumen and asphalt tanker insulation and support pads.

TENMAT is the trusted supplier to major navies worldwide. More than 35 navies specify FEROFORM and RAILKO for safety critical applications where their excellent performance, in abrasive conditions, offer the best combination of durability, low friction and low wear rates in the market place. TENMAT marine bearings have been fitted on a wide range of naval vessels, including patrol boats, corvettes, frigates, destroyers, submarines, aircraft carriers, mine hunters and remotely operated vehicles (ROVs).

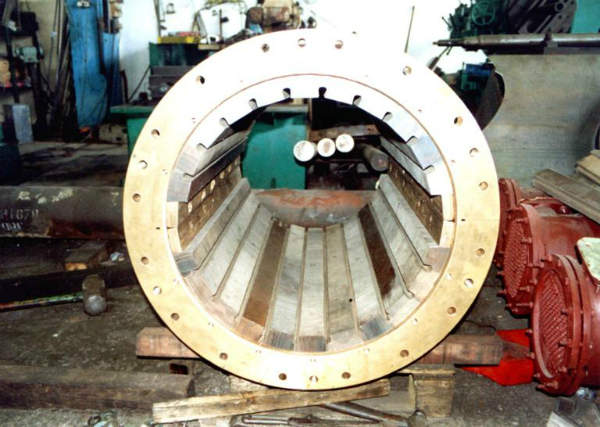

TENMAT FEROFORM grades and RAILKO NF are thermoset composite bearings manufactured by TENMAT in Manchester, used worldwide on newly built vessels, and are available for maintenance purpose, as well as retrofit bearing upgrades from thermoplastic or elastomeric bearings.

Navy-approved engineering materials

The UK Navy approved TENMAT FEROFORM and RAILKO bearings on their submarines, frigates, destroyers, tankers, support vessels and aircraft carriers, which provided low friction measurements, absence of stick-slip, and reduce wear on metal shaft liners.

RAILKO bearings were specified by the French Navy’s surface vessels and Nuclear Submarine due to the silent running of the TENMAT marine bearings.

Specifications for TENMAT bearings were also given by the Indian Navy for its new IMS Kamorta sub-hunter frigate, where silent-running bearings are paramount.

The Ecuadorian Navy approved RAILKO bearings for their SS Submarine due to low water swell, low friction and low stick slip. Benefits providing solutions for safety-critical applications.

Submarines

TENMAT marine bearings have been specified and installed in more than 120 submarines for deployment worldwide, from arctic to tropic seas. FEROFORM and RAILKO composite materials are approved and used by navies for propeller shaft and rudder bearings in submarines where reliable bearing operation is vital.

The low friction and low stick-slip of TENMAT composites give a natural low noise signature that is ideal for stealth operation. Their reinforced matrix structure, using highly specified engineering fibres, anti-scuffing resins and integral lubricants, successfully absorbs shocks and vibrations. This gives significant reductions in noise and enhances bearing life, even in estuarine waters.

Product and services

Tenmat Material Benefits

FEROFORM and RAILKO composite materials are widely recognised as the industry standard for demanding applications such as stern tube, propeller and ‘A’ bracket bearing, rudder bearings, deck equipment and many other military applications.

- Market-leading wear performance: resistant to abrasion and arduous conditions and consistently exhibits lower wear rates against all competitive materials, hence longer life

- Does not require clean water systems: superior resistance to abrasion in arduous conditions and sand-laden waters.

- Excellent stability: minimal water swell and low thermal expansion allowing tighter clearances, ensuring longer life

- Low friction, low stick slip equals low noise: lower noise levels due to lower friction levels and tighter tolerances

- Shaft friendly: excellent with stainless steel, gunmetal, and nickel aluminium bronze counter faces, alongside other common shaft materials

- Accepts misalignment: capable of absorbing high shock loading, therefore accommodating misalignment without damage or fracturing

- Approved by all major classification societies: FEROFORM and RAILKO marine bearings boast full approvals from all leading marine classification bodies worldwide

- Significant worldwide stocks: stocks of FEROFORM and RAILKO tubes are held at strategic locations worldwide, allowing for immediate despatch to any location

- Environmentally friendly: when operated as water lubricated bearings with no contamination from oil or grease

- Works with all lubrication systems: can operate with sea water, oil, or grease lubrication and even dry operation

- Easy to machine, fit and install: available in sheets, tubes, and fully machined components, as well as complete bearing packages with bronze housings

About TENMAT

The TENMAT success story began more than 100 years ago in Trafford Park, one of the world’s first planned industrial estates and still the largest of its kind in Europe. It has been here at TENMAT, where some of the world’s first non-asbestos composite materials were developed, manufactured and supplied worldwide.

Since the 1990s, the company has experienced unparalleled growth, expanding to become a multi-national corporation with presence in the UK, Italy, Sweden, the US, Germany, and France. In 2006 TENMAT acquired Railko, further strengthening its leading position in the rail and marine markets.

TENMAT manufactures a diverse range of thermosets, thermoplastics, hard metals, engineering ceramics, intumescent, and refractory products. TENMAT components offer outstanding resilience, toughness, wear protection, temperature resistance, and long lasting performance.

Contact TENMAT today to receive further information about FEROFORM and RAILKO bearings and other proven solutions for Marine applications.