Long respected for the strength of its helicopter designs and engineering excellence, Kaman’s helicopters division is expanding its focus to meet the growing demands of the rotorcraft industry. As a result, some of the biggest names in aerospace are seeking out the company for comprehensive support, value-added engineering and manufacturing and integration services.

SH-2G(I) Super Seasprite advanced intermediate maritime helicopter

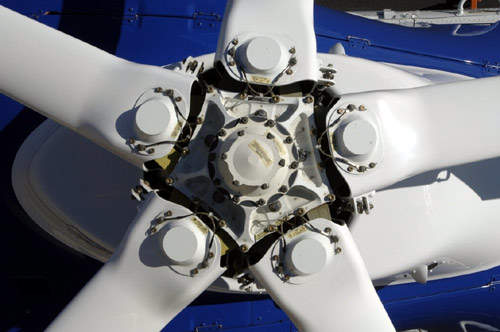

As a pure Maritime helicopter, the SH-2G(I) is the latest and most capable variant of Kaman’s H2 series. It is fully equipped to perform a wide variety of naval missions, including surface surveillance, anti-surface warfare, anti-submarine warfare, search and rescue, contact investigation, and troop deployment, as well as a full complement of utility missions.

The SH-2G(I) features fully integrated tactical avionics systems – ITAS – that are capable of being effectively operated by a crew of two. It is deployable with all classes of naval ship including offshore patrol vessels, corvettes, frigates and larger vessels, and it is full mission capable in extreme sea states and severe environments from the Arctic to the equatorial regions.

SH-2G Seasprite multi-role helicopter

Kaman’s first international customer for the SH-2G Super Seasprite helicopter, the Egyptian Air Force, is entering its 11th year of successful robust performance displayed by its SH-2G(E) helicopter fleet. The multi-role maritime helicopter performs in the extremes of the hot, sandy desert and the humid maritime environment of shipboard service, providing anti-submarine warfare capabilities, anti-ship surveillance and targeting, and search and rescue missions.

Other international militaries using the Seasprite helicopter include the Polish Navy and the New Zealand Navy and Air Force. During a joint training exercise conducted in September 2008 involving the NZ Frigate Te Kaha and an NZ Air Force P-3 Orion, the New Zealand Navy and Air Force successfully fired two live AGM-65 Maverick, air-to-surface missiles from SH-2G(NZ) Super Seasprite helicopters. The simulated targets were floating shipping containers off Great Barrier Island.

Recently quoted in the New Zealand Herald, Commander Mat Williams, commanding officer of HMNZS Te Kaha, said the firing was very successful, stating: "The air-to-surface missile performed as expected and has proven the capability."

K-MAX® and FIREMAX firefighting and disaster relief support helicopters

K-MAX and FIREMAX support helicopters continually prove their extraordinary ability to deliver on-target water and chemical retardant drops in the most treacherous of conditions. In recent history, K-MAX and FIREMAX have supported hundreds of firefighting and disaster relief missions across the western United States, consolidating a reputation for reliability and efficiency. During recent firefighting support and logging work in the Pacific Northwest, one K-MAX pilot reported that his helicopter had surpassed a record flight time of 20,000 flight hours, providing testament to the endurance of the K-MAX range.

K-Max manned / unmanned multi-mission helicopter

Kaman have recently teamed up with the world-leading aerospace company Lockheed Martin to deliver advanced manned and unmanned helicopter systems for worldwide government applications. Initial efforts will focus on the proven performance of the K-MAX aerial truck and the early success of the unmanned BURRO Program, which has already clearly demonstrated its ability as a vertical replenishment and support helicopter in both manned and unmanned configurations.

Using its systems integration expertise, Lockheed Martin will focus on developing advanced unmanned aircraft systems (UAS) flight control for truly autonomous military operations, providing mission-specific avionics, sensors and weapons solutions.

Helicopter manufacturing and support center

Delivering solutions to the world’s prime rotary and fixed wing manufacturers, HeliworX is located physically and functionally within the Kaman headquarters site in Bloomfield, CT. HeliworX is the subcontract arm of the Kaman helicopters business operations.

Backed by Kaman’s existing infrastructure, HeliworX is the only subcontractor with the OEM advantage, capable of offering design/analysis, manufacturing and test and flight solutions for an over-stressed industry.

Kaman’s HeliworX helicopter support capabilities include engineering services and composite manufacturing facilities comprised of various sized autoclaves and in-house processing, metallic manufacturing and final assemblies, rotor blade whirl towers, sand erosion test facilities, and flight testing technologies.

HeliworX is currently delivering quality helicopter and fixed wing products to aerospace industry leaders. The capability usually expected from an OEM is now available from a subcontractor – HeliworX.