For over 30 years, SCHOTT has delivered a wide range of leading-edge glass and glass-ceramic solutions for defense and security applications. SCHOTT’s optics, fiber optic, armor material and electronic packaging products are being used in the field today to keep soldiers safe and to improve their effectiveness. In addition, SCHOTT is working with military and defense industry partners to develop new products that will further improve soldiers’ ability to confront the military

challenges of the 21st century.

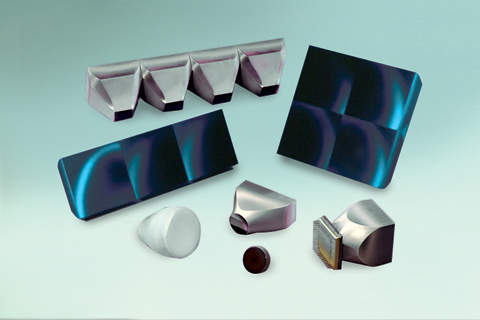

Custom military fiber optics

SCHOTT’s fiber optic products are enabling the defense industry to develop and produce night vision, display and other technologies that are smaller, lighter and more effective. In addition, SCHOTT’s glass research and engineering expertise enables it to develop custom-built fiber optic solutions for new types of military applications.

- Fiber optic defense industry products that SCHOTT currently supplies or is developing with its defense industry partners include:

- Image inverters for image intensifier night vision systems

- Tapers and faceplates for helmet mounted displays (HMDs), used by helicopter pilots, tank personnel and infantry

- Focal plane array components for unmanned aerial vehicles (UAVs), allowing them to capture 120-degree field-of-view video images

- Floating display fiber optic faceplates that reduce ambient light signatures and improve handheld, vehicle and avionic display visibility

- Optically contoured fiber optic components that enable pilots to more easily view information on heads up displays (HUDs)

Standard and bespoke optics

SCHOTT offers the defense and security industry both standard and custom designed optics to meet specific defense requirements.

Using these materials, SCHOTT currently provides the defense industry with:

- Infrared (IR) filters that make it possible for soldiers to use tactical illumination in combination with night vision systems

- Night vision glass and filters that enable soldiers to "own the night"

- Laser glass, calcium fluoride and fused silica used in high energy laser applications

- ZERODUR®, a zero thermal expansion glass-ceramic for mirrors in surveillance satellites, tracking systems and other mechanical or optical applications where a high degree of mechanical stability at a wide range of temperatures is required

- High quality lenses that take advantage of the wide range of SCHOTT’s unique glass and materials technologies to reduce the size and weight of binoculars, night vision systems and surveillance devices

- Contrast enhancement filters that make vehicle and avionic displays readable in challenging tactical environments

- Optical glass for fingerprint and retinal scanning equipment and other biometric applications as well as thin glass for robust, scratch-resistant touch screens

- Radiation shielding glass for use in nuclear waste treatment facilities and other nuclear applications

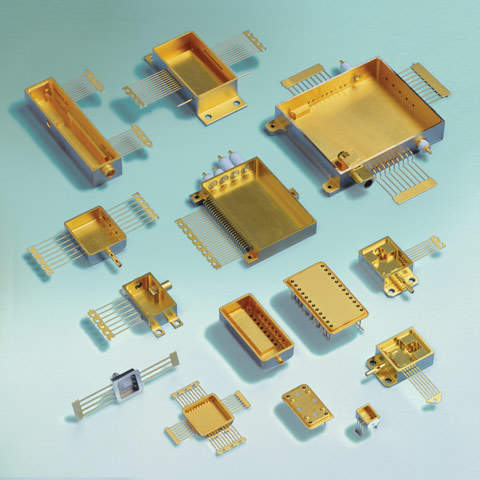

Electronic packaging technology

SCHOTT develops and produces glass-to-metal seal (GTMS) and ceramic-to-metal seal (CerTMS) electronic packaging technologies for the defense industry. SCHOTT’s decades of military business experience and superior technological expertise ensure that these technologies provide exceptional levels of functional safety and protection of sensitive electronic devices.

SCHOTT’s high quality hermetic housings are manufactured with state-of-the-art controlled processes to ensure they meet the strictest customer requirements and fulfill MIL Standard specifications.

SCHOTT’s hermetic packages can be used for a variety of military applications:

- TO (transistor outline) headers and caps for semiconductor, laser, datacom and sensor products

- Opto-electronic housings, such as fiber-optic butterfly packages, for high frequency optical devices and radar systems

- Stainless steel pressure sensor components for avionic braking systems

- Power, relay and DC-DC converter packages for avionic electronics

- Frequency control oscillator packages for quartz timing and mobile communications products

- Hermetic feedthroughs for vehicle safety, engine control and battery-end-seals

- Large scale feedthroughs and penetrators for power generation plants, submarines, ships and pressurized container construction

- Special glass products for sintered preforms, sealing and encapsulation of components

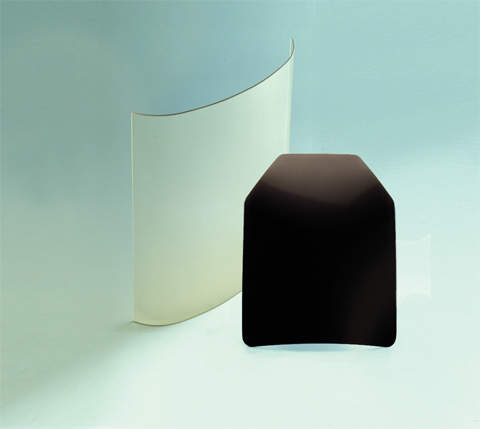

Glass for transparent armor systems

SCHOTT is producing and developing armor substrate materials that offer superior ballistic performance at a lighter weight than current materials. SCHOTT glass is used in transparent armor systems in the field today, and SCHOTT and its defense industry partners are testing and modifying other commercial glass and glass-ceramic materials for use in future defense armor systems.

SCHOTT is helping meet the army’s demand for armor that weighs and costs less, but still offers the protective qualities needed to make soldiers safe, with:

- BOROFLOAT® borosilicate glass, a lighter and clearer alternative than other kinds of ballistic glass materials

- New types of opaque armor substrates that could enable the military to lighten soldiers’ loads by creating personal armor systems that weigh less than current systems yet are just as protective

- Glass-ceramic substrates for vehicular armor systems that are more effective and weigh less than current substrates