Seastema S.p.A., a Fincantieri Company, is a global supplier of integrated automation and control systems (IACS) for naval and maritime industries

Seastema has grown rapidly in the last years thanks to the attention to the customers’ needs and the continuous improvement of the portfolio with strategic products and innovative solutions that help customers and end users to maximise the reliability and the operational efficiency of their ships.

Integrated platform management systems (IPMS) for naval ships

Combining cutting-edge technology in process automation with leading expertise in ship-building, Seastema has developed SEASNavy™, the integrated platform management systems (IPMS) for naval ships that grants a high level of integration and automated features. SEASNavy™, is the step forward in marine automation technology.

SEASNavy™ helps Seastema’s customers to improve the ship operability in terms of safer and more efficient operations and in terms of operating costs reduction.

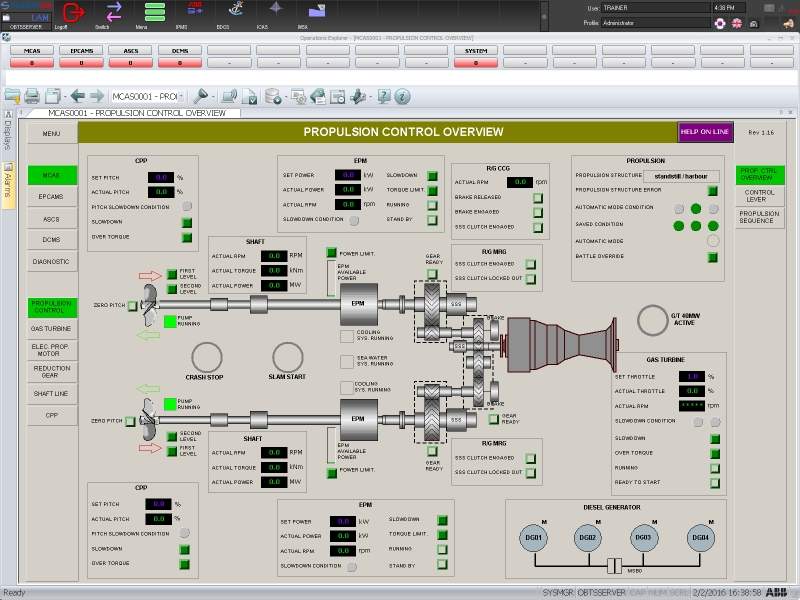

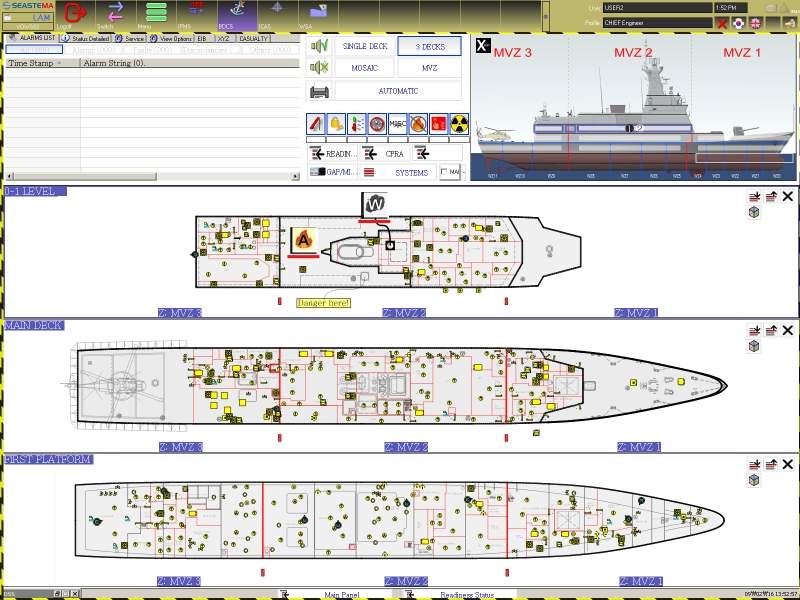

The typical scope of supply includes monitoring and control of marine machinery equipment, electrical and power generation systems, hull services, ship services and safety systems. All systems are designed to guarantee the highest level of redundancy for the maximum of availability, along with ship survivability and operability in case of damage or emergency conditions.

A sophisticated set of specialised libraries, combining full access to all information and subsystems functionality with simplified operating functions that optimise crew intervention, are what make SEASNavy™ IPMS extremely appreciated by the end user customers.

IPMS standard supply:

- Power management system (PMS)

- Propulsion control system

- Machinery auxiliary monitoring and control

- Hull services control and monitoring

- Battle damage control system

Additional features:

- Naval integrated condition assessment system (ICAS)

- On board and ashore training systems

- Propulsion dynamic simulation

- Energy management system

- Integration of bridge systems

- Navigation data distribution unit

- Integrated dynamic positioning

System reliability and availability

System reliability and availability are guaranteed by the system design requirements: fault tolerance, multi-level redundancy and the ability to withstand the toughest marine environments but also by other characteristics that help to minimise the time to restore like advanced self-diagnostic tools, configuration online and easy maintenance procedures.

All systems are certified in accordance with the relevant MIL standards.

Integrated marine automation technology

The basic design of the automation system starts with the preliminary stage of close cooperation with the navy to define the most efficient solution for them, while also taking into consideration the warship’s characteristics and operational requirements.

Our considerable experience demonstrates that this approach results in a ship management system, which provides added value to the whole ship.

Life cycle services

Service activities begin with the ship’s operation and last for its entire lifetime. To assist navy officers all over the world, Seastema can rely on a flexible service organisation that often involves also technical partners based in the operative area of the ships.

The life cycle concept, the large use of COTS products available everywhere and the service organisation ensure high-system availability during the entire ship operating life.

Some of Seastema SEASNavy™’s most significant projects include:

- Korean Navy, FFX-II Frigate (in progress), shipyard DSME

- Italian Navy, FREMM Frigates, shipyard Fincantieri

- Italian Coast Guard, Multirole OPVs, shipyard Fincantieri

- UAE Navy, Anti Submarine Warfare Corvette, shipyard Fincantieri

- Indian Navy, Fleet Tankers, shipyard Fincantieri

- Turkish Coast Guard, Offshore Patrol Vessels, shipyard RMK

- Italian Navy, Air Craft Carrier, shipyard Fincantieri