IFEN Ing. Amedeo Lia Industria Forniture Elettriche Navali, founded in 1951 and based in Ceparana (La Spezia), Italy, is divided into two divisions: a naval magnetism division and an electrical division.

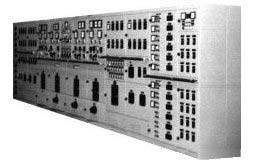

The naval magnetism division is particularly concerned with the design, manufacture, installation and testing of magnetic protection and degaussing systems. The electrical division concentrates on the design and construction of electrical products such as main switchboards, control panels, power distribution cabinets and related equipment.

Naval magnetism division

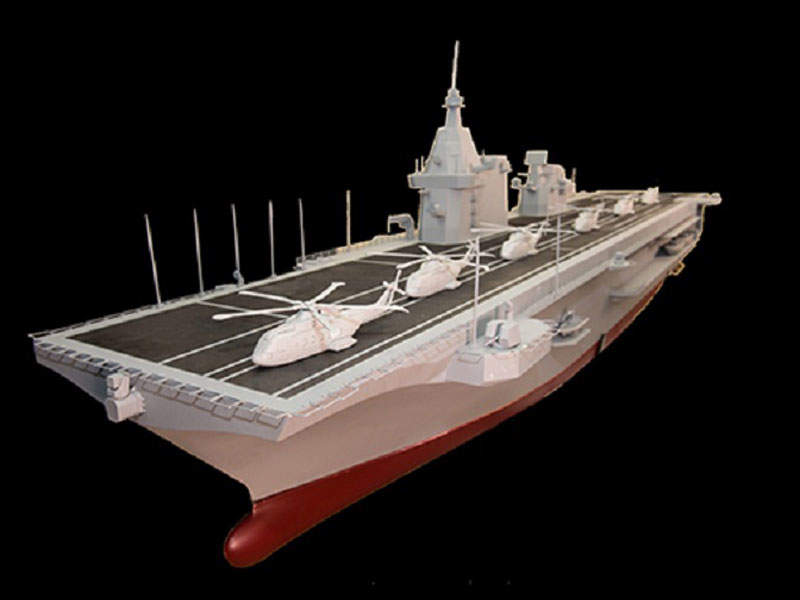

IFEN has been involved in the area of naval magnetism from the very beginning, having designed and manufactured degaussing systems for steel surface vessels and low magnetic signature MCM vessels for the Italian Navy, amongst others.

During 50 years of experience in this field, IFEN has designed, manufactured, tested, installed and calibrated degaussing systems for over 150 ships.

IFEN’s activities have grown considerably over the years, and today includes degaussing equipment design and construction, degaussing coil design, and on board installation and calibration of the overall system at sea.

Thanks to such a complete experience, IFEN is capable of undertaking full responsibility for the supply of degaussing systems meeting the customer’s requirements and specific magnetic-protection levels.

DGM4 and DGM5 degaussing systems

For low magnetic signature vessels in particular, IFEN can supply dedicated, new-generation automatic degaussing control systems, which all belong to the DGM4 family.

The DGM4 is the degaussing control system designed with IFEN’s worldwide experience.

The newest classes such as Osprey (US Navy), Lerici II / Gaeta (Italian Navy), and Oksoy and Alta (Royal Norwegian Navy) are compatible with DGM4.

For steel-hulled vessels, we offer a new-generation degaussing control system: the DGM5.

Magnetic modelling and degaussing research

During the 50 years of business, IFEN has acquired a broad understanding of the different fields of magnetism, such as:

- Design and development of new innovative degaussing technologies (including closed loop degaussing) and related degaussing control equipment, systems and utilities

- Development of project-tailored magnetic silencing plans and provision of full assistance for their correct application

- Research and implementation of empirical, theoretical, and computational methods for magnetic modeling of equipment, system and ships

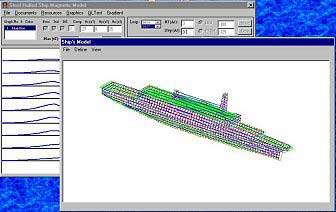

Starting with theoretical model and calculations made using specialized software tools (designed, developed, and validated by IFEN experts), IFEN estimates a ship’s undegaussed signature and processes the most effective degaussing system project.

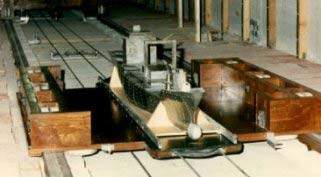

Further theoretical and computational results, as well as system projects, are validated by comparison with historical experimental data and / or measurements made in the land-based magnetic range on magnetic scaled down models.

Finally, after the onboard installation and testing of the degaussing system, IFEN performs system calibration at degaussing range within the customer’s requirements.

Particularly during the last years, IFEN has studied, developed and demonstrated closed loop degaussing, and is currently upgrading the DGM4 system installed onboard the Italian Navy Gaeta class to incorporate such new and outstanding capabilities.

Land-based magnetic range

Furthermore, IFEN has established a dedicated magnetism laboratory for development and study of mathematical models and computational approaches to electromagnetism topics, as well as experimental validation of new degaussing techniques and equipment.

The land-based magnetic range was designed and built by the naval magnetism division, and constitutes the main facility among the others used for design, R&D and measurements.

Land-based magnetic range capabilities are:

- Measurement of the magnetic ‘signature’ of a test sample at specified distance in a controlled environmental magnetic field

- Magnetic normalisation treatments (i.e. deperming) on ferromagnetic components to reduce permanent magnetisation and bring it into a stable condition

- Susceptibility tests to high-intensity magnetic fields on equipment of even large dimensions

Ruggedised electronic equipment

IFEN’s design and production is specialized on custom ruggedised electric and electronic equipment, capable of withstanding particularly hostile environments.

Compliance with the most severe military standards for high shock (MIL-S-901), vibrations (with MIL-STD-167-1), temperature and humidity, and EM compatibility has been, and still is, an outstanding aspect of our products, as demonstrated by their successful testing.

All IFEN’s products are designed, manufactured, and fully tested at IFEN’s own facilities.

All the above mentioned activities are integrated with a quality assurance system which is certified to NATO AQAP-120 by the Italian Navy and also meets the requirements of ISO 9001 – NATO AQAP-110.