COFI has 35 years of experience fitting Italian and foreign navy units, with a specialism in the design, manufacture, supply and installation of fluid-transfer components for onboard plants. Our main products include: anti-shock rubber expansion joints, flexible hoses, dog leg, fabric and metallic expansion joints, seal systems and special equipment. Our entire product range is certified and meets the highest safety and quality standard for navy applications.

COFI offers tailor-made technological solutions and an engineering problem-solving service, with high reliability and quick timing. We guarantee 24/7 support after purchase, thanks to our Dbflex® management software.

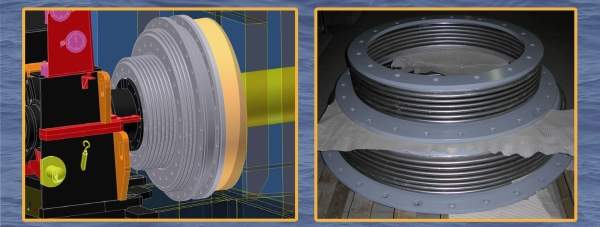

Anti-shock rubber expansion joints

Coflex©D rubber expansion joints represent a real technological innovation in the anti-shock field. Their main function is to preserve machinery from shock due to explosions, particularly underwater mine explosions.

Other features include:

- Vibration absorption

- Noise insulation

- Thermal mismatching compensation

Onboard plant applications include: power, conditioning, refrigeration, and other vital plants.

Born to meet the increasingly strict safety standards of the Italian navy units, COFI designed and created a shock test machine that evaluates a new joint performance. Something which previously had never been created, the shock test machine assesses each joint performance with more than 150g of shock acceleration and more than 110mm of lateral offset. This expansion joint is fire-resistant for more than 30 minutes at 800°C (tested by RINA), according to the MED directive, thanks to the protection of our flame protection cover, type Coflex®CF1.

The CoflexD is resilient and works within the following conditions:

- Works with all fluid types

- Can work to a minimal temperature of -10°C, maximum of +90°C (up to +120°C)

- nominal pressure 16 bar

The standard size for CoflexD ranges from DN40 to DN250 (mm of nominal diameter), but we can provide tailor-made solutions. This compact device (150mm in length) allows machinery to achieve high safety standards with an extremely light and space-saving solution, unlike any item on the market. Because of its high anti-shock standards and quality, CoflexD is especially suited for submarines, mine-hunters and mine-layers, but is compatible on all types of vessels.

Dog leg, flexible hoses, fabric and metallic expansion joints

COFI supplied warships with a wide range of anti-shock items, including:

- Dog leg, characterised by huge noise reduction and vibration absorption of a maximum of 15dB at 1kHz

- Flexible hoses in NBR rubber for all fluid-type movement

- Metallic expansion joints, for high-temperature fluid transfer

- Fabric expansion joints, for main engine combustion air and exhaust gas ducts

All of these products are fire-resistant according to MED, thanks to COFI flame protection covers.

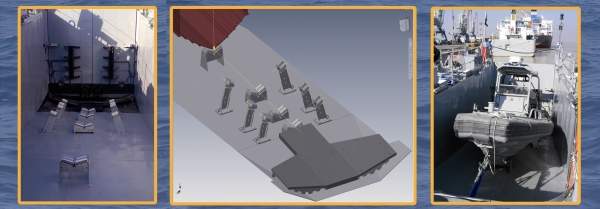

Special seal systems

COFI specialises in the design and manufacture of special seal systems, like the elevator gasket of Cavour aircraft carrier used by the Italian navy, and the shaft telescopic bulkhead passage of SAR-class coast guard boats used by the Turkish navy.

Tailor-made technological solutions

COFI creates custom-made technological solutions for vessels, like the unlocking device for the safe life system on U212 class submarines, composed of the sphere fastening belt, dumpers, couplings and unlocking mechanism, and also the hauling and launching fast system for Saettia Mk4 class patrol boats for the Iraqi navy.

Dbflex® managing software

COFI produces the programme Dbflex® multi-platform management software system. It contains data, documents and certificates of items on the ship to facilitate easy management, maintenance and deadlines of items onboard plants. It is applied successfully to monitoring all the installed items on the Italian navy units and supporting onboard maintenance.