At Rolls-Royce we work closely with our customers to develop innovative, value-adding solutions that will fully meet future requirements.

Our capability in ship design was recently broadened with the setting up of a naval design team. This team will leverage innovation and technologies from our fuel efficient commercial and offshore vessel designs, with products adapted and integrated for specific naval requirements.

A number of the world’s coastguards already use Rolls-Royce-designed vessels for EEZ duties, and more than 70 navies around the world use our power systems and equipment.

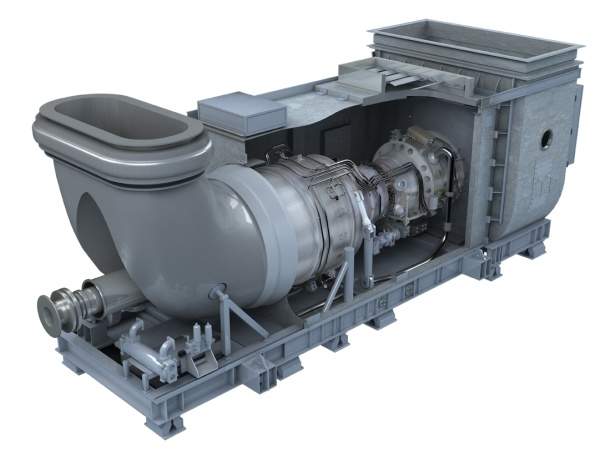

Marine gas turbines

The MT30 marine gas turbine is the world’s most powerful marine gas turbine. It incorporates the latest gas turbine technology to deliver efficiency with reliability.

Derived from the Rolls-Royce Trent aero engine family, with mroe than 50 million service hours, the MT30 has been selected to power four of the 21st century’s latest naval platforms. It can deliver its full power of 36MW in ambient temperatures up to 38°C.

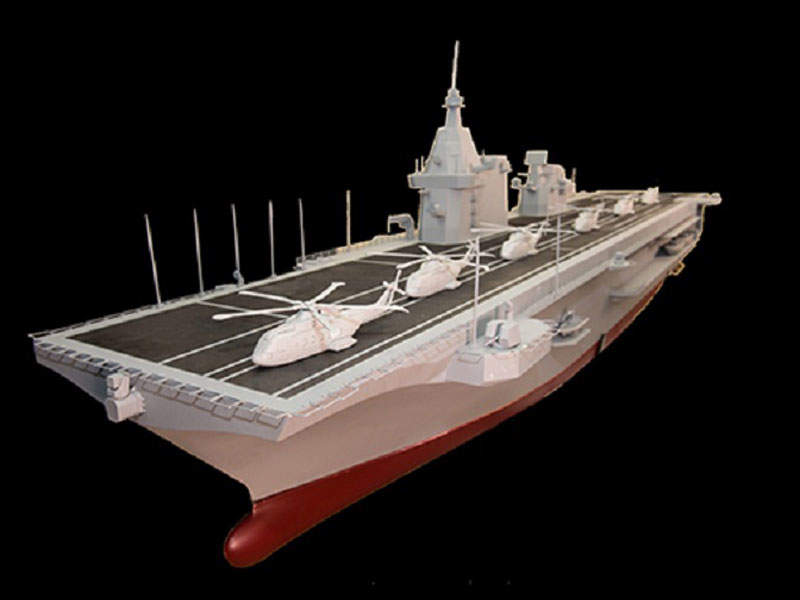

2008 marked the MT30’s entry into service, powering the US Navy’s first littoral combat ship USS Freedom. The engine has been ordered to power another ten of the class and selected to power the latest FFX frigate for the Republic of Korea Navy. MT30 alternator packages will power the UK Royal Navy’s new QE class aircraft carriers and the US Navy’s DDG 1,000 multi-mission destroyers. Rolls-Royce has recently been awarded a contract to design the gas turbine system for the Royal Navy’s future Type 26 Global Combat Ship, which will, subject to contract, feature the MT30.

Gas turbines and diesel engines

For smaller high-speed craft the MT7 marine gas turbine delivers powers from 4MW to 5MW, and is derived from the AE 1107 engine that powers the V-22 Osprey tilt-rotor aircraft. It has recently been selected to power the US Navy’s new ship-to-shore connector (SSC) hovercraft.

Since March 2013, MTU has been owned by a joint venture company set up by Rolls-Royce and Daimler to form a formidable power and propulsion solution company. The combination of MTU and Bergen engines greatly enhances the existing Rolls-Royce range of propulsion equipment. With a new portfolio of medium and high-speed engines, customers are provided with innovative high quality, cost-efficient marine systems.

Rolls-Royce and MTU have been selected to design the propulsion system for the British Royal Navy’s new Type 26 frigate program. These vessels will feature a combined diesel-electric or gas-turbine propulsion configuration comprising four MTU 20V 4000 M53B diesel gensets with a single Rolls-Royce MT30 gas turbine. The diesels provide power for on-board systems and cruise mode, while the gas turbine is switched in for high speeds.

Propellers and thrusters

Rolls-Royce is a world leader in propeller and propulsor technology. The Kamewa® and Bird-Johnson controllable and fixed pitch propeller designs are normally custom-designed for each naval application, with testing conducted in-house at our Hydrodynamic Research Centre in Sweden.

A fixed pitch unit, the Kamewa adjustable bolted propeller (ABP) propels the Royal Navy’s Type 45 destroyers and will be fitted to the QE class carriers. Blades can be adjusted or replaced using hand tools. Azipull azimuth thrusters are suited for higher speed vessels requiring high manoeuvrability with dynamic positioning. Our other products include azimuth thrusters, retractable thrusters, podded propulsors and lightweight submarine propulsors.

Waterjets

Our Kamewa waterjet range is the broadest in the business with installations in more than 20 different naval classes, plus a variety of fast patrol craft and RIBs. New levels of stealth have been achieved with the naval design that powers the Visby class corvettes. Mixed and axial flow models are available in aluminium and stainless steel for powers from 200kW to more than 30MW.

Submarine nuclear propulsion

Rolls-Royce is a world-leader in nuclear submarine systems and support services incorporating design, procurement and operation. We are the technical authority for the UK Nuclear Steam Raising Plant (NSRP), which is responsible for powering the whole of the UK’s Royal Navy submarine fleet.

Our role covers all major activities – design, project management, procurement and safety assessment. Worldwide submarine operational support is provided from Derby and through support staff at naval bases throughout the UK.