Seafury International’s surface drives and surface piercing propellers have been in production for over twenty years, supplying law enforcement, surveillance, military, commercial and strike craft throughout the world.

Robust reliability has been the result of extensive research and development, resulting in a product that is simple, uncomplicated in design, low in maintenance and high in performance. Seafury’s equipment is manufactured to the highest of marine standards.

High efficiency surface drives

Seafury surface drives operate aft of the vessel at water surface level, thereby eliminating the shaft drag co-efficient of conventional systems. This alone makes them 10% – 20% more efficient in the higher speed ranges.

Significantly higher speeds can be achieved with the same engine horse power compared to conventional propellers & water jets in higher speed ranges.

Seafury’s design efficiencies harnessing maximum torque using carefully designed and developed varying pitched blades. Seafury vessels travel further for the same fuel burn.

Low maintenance, high-performance surface drives

The surface drive’s simple, robust design and high quality marine components and manufacture ensures extremely low maintenance and high performance. With no hydraulic steering or articulated drive system being exposed to the harsh marine environment, maintenance is much easier and significantly reduced.

Seafury was the world’s first propulsion manufacturer to specify a 45° transom, ensuring thrusted water goes under the vessel providing excellent astern / reverse and close handling performance. Should your vessel not have a 45° transom it is easily overcome by the addition of pods.

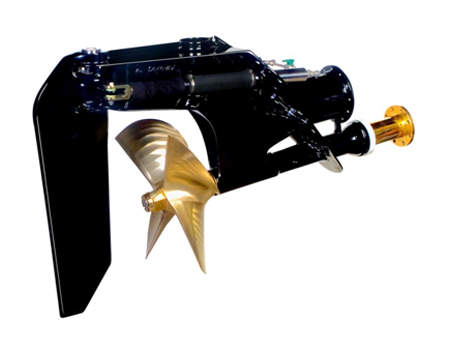

Surfacing-piercing propellers for fixed-shaft surface drives

Seafury surfacing piercing propellers are designed to suit fixed-shaft surface drive systems. Their graduating pitch zones ensure that the propeller is appropriately loaded throughout the speed range, negating the need for a trimable drive. This is easy for the operator and offers a quiet smooth ride.

The unique propeller design means crafts are quicker to the plane with minimal lazy speed range. Example: 10 seconds from idle to 45 knots for a 22 tonne mono hull with two 1200HP engines.

As the propeller is positioned aft of the transom and forward of the rudder and being only half submerged when in operation, there is minimal chance of propeller damage. This design also offers enhanced safety for passengers and crew.

Ship propulsion systems

Seafury offer a complete propulsion solution, from speed calculation, vessel design, engine horse power and gearbox ratio selection through to the supply of the appropriate system. Our package includes drive body, drive shaft and gearbox couplings, hydraulic steering cylinders, rudders and surface piercing propellers. The complete package comes with simple bolt on instructions.

Seafurys’ mission statement

Seafury is proud to be the driving force behind numerous customs, military and navy fast interceptor vessels. Seafurys’ mission is to continue to be the number one manufacture and supplier of the most Robust and Reliable High Performing Surface Propulsion Systems available on the market.

"Seafury – making surface propulsion reliable".