Cloudis ship cable management software has been in use at major naval shipbuilders since 1996. The cabling for several major projects has been managed using Cloudis’ ICEPIC application. Our more recently developed CMPIC (Configuration Managed Project Integrated Cabling) software builds on our experience with naval customers, and now offers a broader range of capabilities, from design through to installation planning and the management of the installation process.

In addition to the standard functionality available in CMPIC – such as automatic cable routing, status management, change control, etc – there are a number of facilities that will be of particular interest to shipbuilders.

Ship cable applicability or configuration management software

Configuration Management (CM) functions enable the customer to manage cabling across any number of vessels in a ‘class’. The user can apply any cable or associated data to one or any number of vessels in the class. Using CM, the number of vessels in the class is defined up front and from then on the applicability of all cables and associated data are managed by CMPIC.

Configuration rules check for consistency and logic, ensuring that users cannot enter erroneous or inconsistent data.

Multiple construction site ship cable management

CMPIC caters for the modular construction of vessels at more than one yard. A vessel can be broken down into blocks representing the method of construction. Ship cables can be defined as starting and terminating within a block, starting within a block but terminating outside it, starting outside a block but terminating within it or passing through the block.

CMPIC manages the network, routing and installation implications of this type of design and construction.

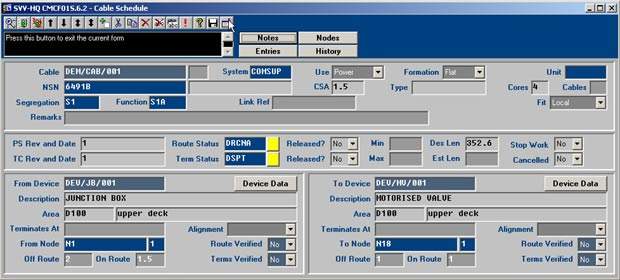

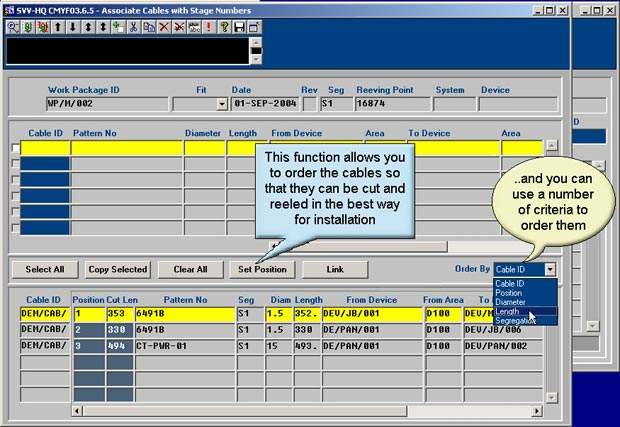

Ship cable installation planning software

The user can create ‘Work Packages’ with which cables can then be associated for installation. These work packages can be defined in any way – e.g. by segregation, block, area, penetration, etc. – and can also be used to derive metrics to assist in future planning.

Ship cable special production features

Three features within the production functionality of CMPIC which are of particular interest to shipbuilders are:

- The setting of ‘tape marks’ on cables to help identify the correct point to which a cable should be pulled – the tape mark can be set from either end of the cable

- The recording of locations of partially pulled cable coils so that they can easily be found for continued installation when required

- Learning from experience, which can be carried forward to subsequent vessels in a class – for example, when cable cut lengths are recorded against cables, the data can be used to avoid cable wastage on future vessels in the class

Multi-site ship cable installation support

Where ship cable installation is carried out on more than one site CMPIC can be used to co-ordinate the activity on these sites. Access to information within CMPIC, which might be sensitive, can be protected.

Segregation management

Where space is at a premium and segregation rules are stringent, the management of segregations is paramount. CMPIC can be configured to allow multiple segregations on the same part of the nodal network. Where this is allowed, segregation spacing can be invoked which is then taken into account in the percentage fill calculation for the nodal network.

CMPIC also caters for the use of Mu-Metal to separate segregations, and takes account of this in its percent-fill calculations.

Conduits can also be scheduled, routed and managed in CMPIC where these are used to enclose cables when on or off the ladders, trays or hangers.

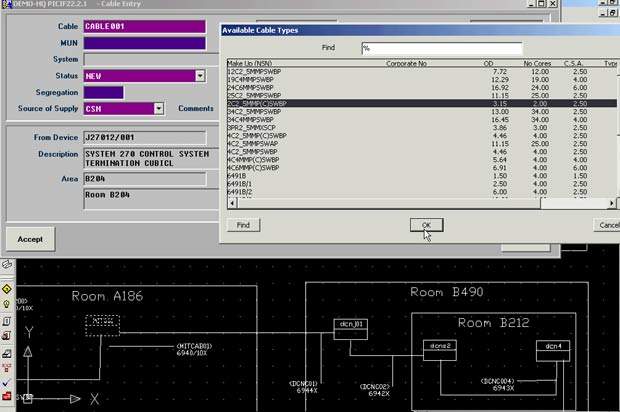

Interface to CAD systems

Our XML interface and API enable CMPIC to work in a generic way with CAD systems, enabling the data required by CMPIC to be extracted from the CAD model and vice-versa. Further development facilities are available for more sophisticated interfaces between CMPIC and CAD should this be required.