MSI designs and manufactures wideband sonar transducers and arrays for commercial and defense customers worldwide.

Applications include:

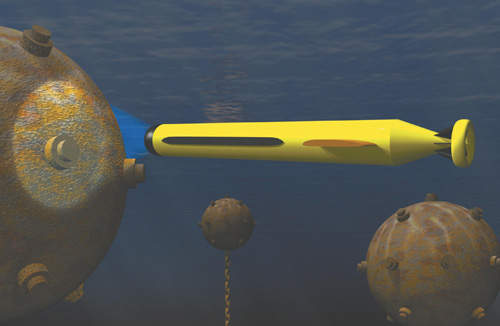

- Mine detection and classification

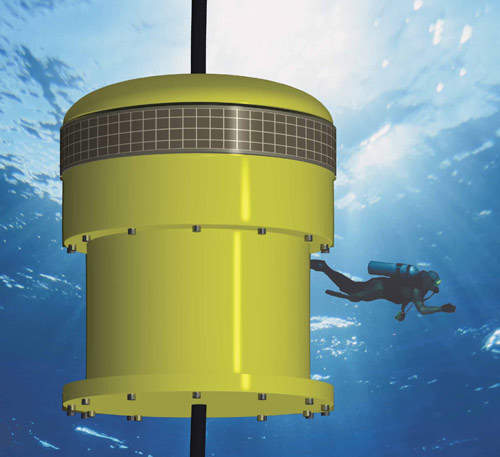

- Swimmer detection

- Port and harbor security

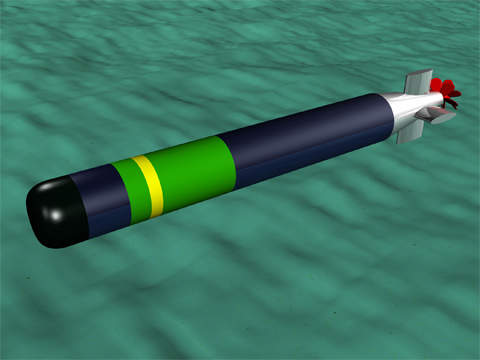

- Weapons sonar (including torpedo homing)

- Parametric sonar for sub-bottom profiling

- UUV and AUV sonar

- Side-scan sonar

- Forward-looking sonar for obstacle avoidance

- Bottom mapping sonar

- Acoustic communications (ACOMMS)

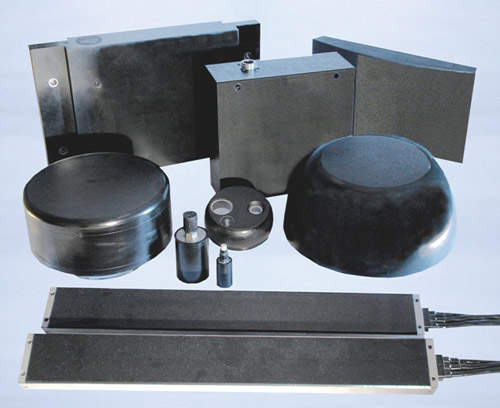

High-Performance Transducers

Over the past 18 years, MSI has emerged as the global leader in designing and manufacturing high-performance piezocomposite transducers for the US Navy and a variety of international defense customers. MSI is also in full scale production for a broad range of commercial and industrial applications, with a high volume manufacturing plant that is vertically-integrated from ceramic production through array assembly and in-water testing. MSI builds custom products to specification or print, depending on customer requirements, with ample capacity for handling high volume transducer production alongside small quantity prototyping.

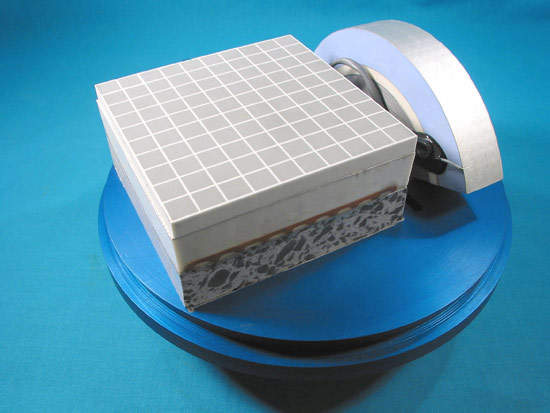

Piezocomposite Transducers

MSI’s piezocomposite technology provides broadband sonar with high receive sensitivity, high source level, and conformability for making curved and shaded arrays with optimal acoustic beam-patterns. MSI’s pioneering development of ceramic injection molding for high volume manufacturing of 1-3 piezocomposite opened the way for applying piezocomposite materials to many new sonar and ultrasound applications. MSI’s wideband piezocomposite sonar transducers enable

phased arrays to operate with multiple beams over distinct frequency bands, allowing greater range and resolution using broad spectrum signal processing techniques.

Sonar Transducers and Arrays

MSI’s piezocomposite sonar transducers and arrays can be curved to conform to a hydrodynamic profile when mounted to the curved hull of a vessel or AUV. Resonant transmit designs are available at frequencies ranging from 15 kHz to over 1 MHz. Receive arrays cover this same range and more, operating as low as 3Hz in passive surveillance arrays. MSI’s piezocomposite sonar materials have been shown to meet full explosive shock requirements for navy operations in both the US and UK, and can be configured for operation at full ocean depth.

Transducer Design and Manufacturing

MSI’s patented ceramic injection molding process allows large areas of piezocomposite material to be efficiently produced in high volume with excellent uniformity. This also permits cost-effective assembly of multi-element arrays with complex shading patterns. MSI’s proprietary array fabrication techniques and custom acoustic backing and matching layer materials are enabling new sonar array designs that produce well controlled beam-patterns with high sensitivity and broad frequency response. MSI’s piezocomposite array technology is providing major performance benefits in many of the latest commercial and defense imaging systems, including US Navy mine-hunting, UUV and AUV.

Acoustic Design, Mechanical and Electrical Analysis

MSI has an experienced staff of scientists, engineers and technicians that specialize in acoustic design, mechanical and electrical analysis, and manufacturing process development. They form an integrated product team dedicated to developing custom sonar transducers to satisfy specialized and proprietary sonar array requirements.

During the transducer design process, our staff works closely with each client to ensure that the resulting sonar products fit within the

customer’s budget as well as meet customer-specified electromechanical requirements. We work closely with our customer’s engineers to ensure that our acoustic transducers and arrays optimally integrate with customer-supplied signal processing electronics. MSI’s quality systems have been audited and certified to the latest ISO 9001:2008 quality standard.