Deep Trekker provides remotely operated underwater vehicles (ROVs) for ocean, sea, lake and river exploration. As well as supplying equipment, the company collaborates with clients, sharing its knowledge and supporting naval operations.

Underwater inspections for the naval defence and inspection

With the launch of Deep Trekker’s REVOLUTION ROV and Diveable Control System, the company has extended its capabilities to meet the needs of numerous industries, including security and naval operations.

ROVs can be used for hull inspections to ensure optimal safety and operational productivity. They can also be used for explosive ordnance disposal (EOD) as a safer alternative to sending a diver underwater to disarm explosives.

Additionally, Deep Trekker’s ROVs can be used for special operations, including recovery missions, surveying for enemy submarines or divers, or search and rescue operations.

Remotely operated underwater vehicles for the naval operations

The DTG3 can reach depths of 200m and features an eight-hour battery life. The ROVs improved viewing and recording capabilities provide better inspections with its live 4K video and handheld waterproof controller.

Using BRIDGE technology, the DTG3 has advanced stability even in hostile underwater environments, in addition to the freedom to move with direct sonar integration, as well as automated station holding that can rotate 270 degrees.

The Deep Trekker REVOLUTION is designed to be tough. It is manufactured from carbon fibre and stainless steel. The ROV features wireless connectivity, augmented recording capabilities, auto-stabilisatio4 and 4K HD video resolution.

Additionally, the ROV has automated station holding, meaning that the camera, sonar, and manipulator arm can rotate 260 degrees for improved situational awareness. It can be remotely controlled to water depths of 305m and the manipulator arm has a close strength of 70lbs, as well as a tether that can pull up to 300lbs up to the surface.

Deep Trekker REVOLUTION is engineered to detect and locate items underwater and can assist divers on search and recovery operations in adverse weather environments as BRIDGE technology enables the ROV to remain stable.

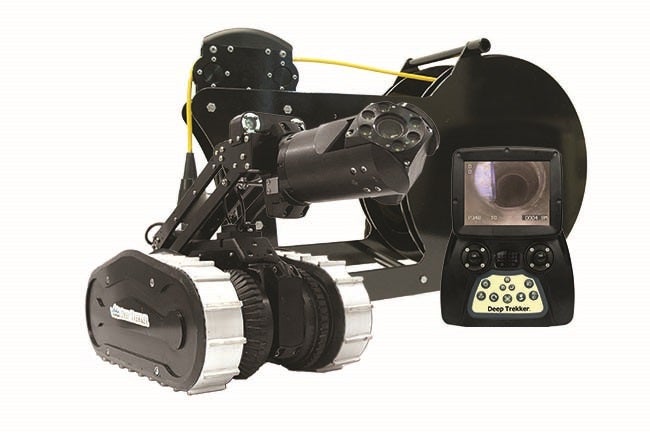

Pipe crawlers for navy applications

The DT340 is manufactured from anodised die-cast aluminium and stainless steel. In conjunction with its sapphire glass camera lens cover, this cover is optimal for adverse environments.

Due to its magnetically coupled drive, this crawler is inherently waterproof and does not require maintenance, such as dynamic seals that need to be greased or replaced. The optional tracks system is made from steel cord, which is reinforced with polyurethane, meaning that it can manoeuvre over any obstacle.

Underwater naval operations are made safer as no power is sent through the tether, which also reduces the crawlers’ pull weight. The thin DT340 is reinforced with synthetic fibres so strength is not compromised.

The DT320 Mini Pipe Crawler is optimised for portability, which enables operators to carry out underwater operations without the need for topside power.

The mini pipe crawler fits inside a compact carry case and can be deployed without generators or onsite power. It is the only battery-operated easy-to-use CCTV pipe crawler of its kind.

Visual catalogues of hull inspections can be built and integrated with asset management software. Additionally, it can be equipped with a number of wheel options and tracks so that the camera can be customised for projects.

Submersible utility crawlers for security and naval operations

The three-wheel DT640 Utility Crawler features a magnetic wheel option to allow for a variety of inspections.

The DT640 is compact and portable and can be deployed from any location. It is designed for reaching difficult to access locations and features a number of customisation options, including vacuuming, pressure washing and thickness testing.

The DT640 Mag provides an efficient and safer alternative to manual hull inspections. Its on-board HD camera allows for a live video feed, providing operations with instant feedback. Its innovative design enables it to latch onto the side of ships and vessels, even during transit.