With more than 30 years of experience in the field of weapon alignment and tracking systems, Schill Reglerteknik (Schill) supplies navies, armed forces, shipyards and system providers worldwide with alignment systems, products and services, providing unmatched shooting accuracy for on-board artillery and other weapon systems.

Static alignment

Static alignment is the control and correction of a system’s mechanical tilt, Azimuth and elevation errors. Schill’s high precision and easy-to-use alignment tools can align virtually any system, providing careful and accurate alignment of a weapons system’s most critical parts.

Static weapon alignment systems

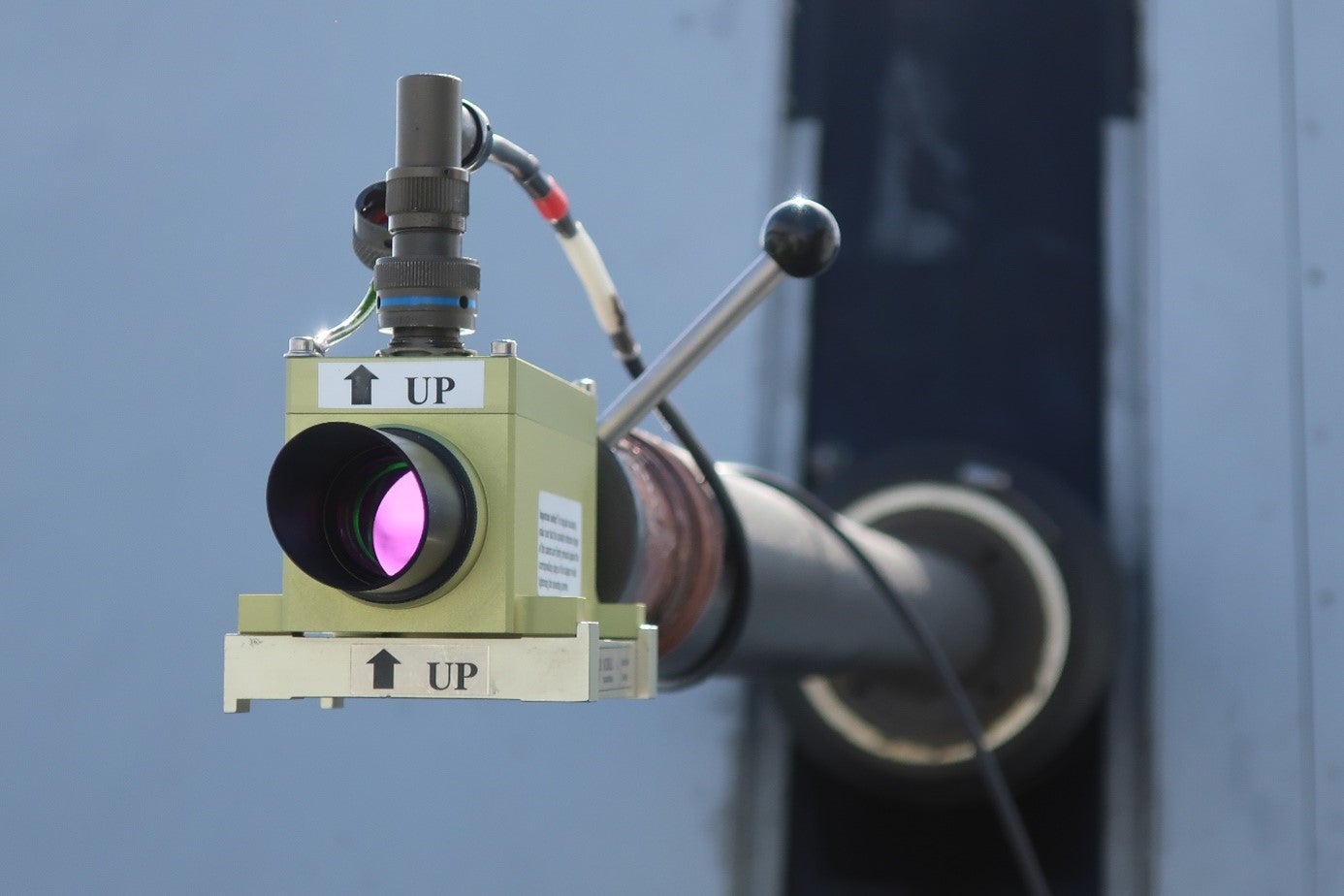

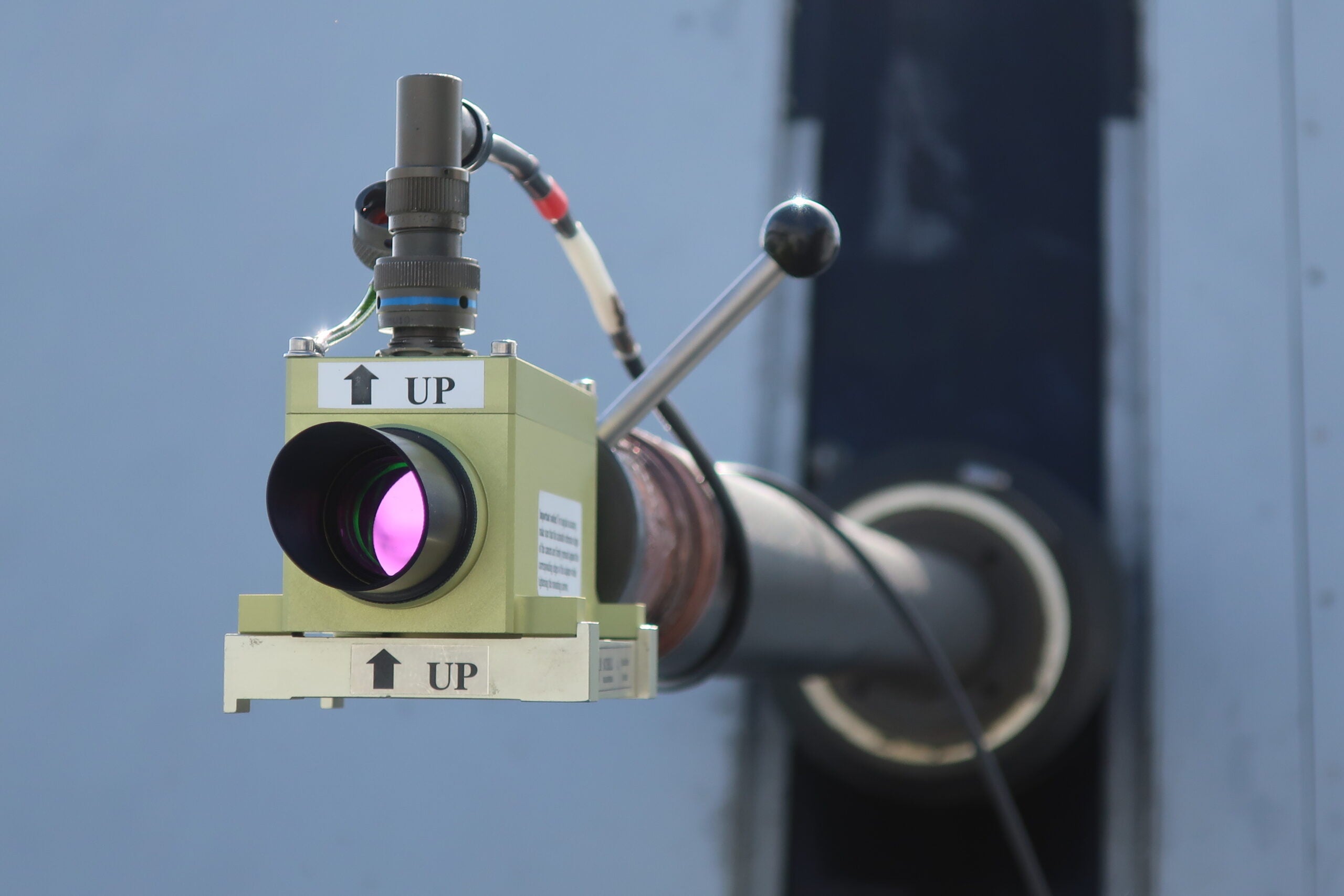

The Schill Aligner 308 makes the task of performing static alignment of shipboard weapons systems easier than ever, saving time and operational costs compared to traditional methods.

Some of the benefits of the Aligner 308 are uncompromised accuracy, a complete range of functions for static alignment, and no required dry-docking. The innovative alignment method also minimises non-operational time thanks to the toolkit, which covers all aspects of calibration, and intuitive handling provided by the simple-to-use guidance software.

On top of standard alignment procedures, the Aligner 308 provides unique functions for complete verification of alignment results. Other superior features include Azimuth measurement between stations, even out of line-of-sight, as well as true gun barrel axis measurement and ship’s gyro performance test.

In summary, the Aligner 308 system enables clients to perform complete weapon system alignment in four to six hours, achieving shooting performance accurate enough for repetitive direct hits on a towed target.

Dynamic alignment

Schill offers a full-featured optical alignment tool capable of the advanced and intelligent analysis necessary for successful dynamic alignment.

Dynamic systems are designed for the triple purposes of finding and correcting alignment verification errors, performing dynamic analysis (finding irregularities in weapon system behaviour), and fault identification. Alignment result data and diagrams, as well as dynamic measurement recordings, are stored in our alignment systems and can be retrieved at any time, providing an excellent base for fault analysis and identification.

Dynamic alignment systems

Schill offers convenient solutions for accurate static and dynamic gun misalignment testing, with products for both quick benchmark tests as well as advanced and fully automatic dynamic alignment.

Schill provides different products depending on the dynamic alignment needs. Basic dynamic alignment features include high resolution and precision with simple and quick gun barrel installation and accurate, self-aligned gun barrel video-camera adapters. The ruggedised and splash-proof hardware comes with a wireless configuration option and is mechanically and optically stable over time and temperature.

On top of these features, the advanced dynamic alignment can have up to four video cameras and four auxiliary video sources connected, as well as up to four video sources concurrently displayed. The simultaneous display of two or more video sources on-screen allows for real-time error tracking and evaluation. The advanced systems also include video tracking for automatic alignment analysis, precision video cameras with high-brilliance video, video recording to disk, and voice recording for real-time comments, as well as other features, such as electronic crosshairs, zooming and contrasting.

In summary, Schill’s dynamic aligners enable users to perform a full ship weapon tracking evaluation in two to four hours with detailed analysis that can be assessed later using replay of recorded video, voice and data.

Alignment services

Schill is independent of weapon manufacturers and has extensive expertise within the field of alignment. We have completed alignment assignments worldwide.

Today, Schill offers customers a range of services, including static and dynamic alignment of naval weapon systems, training courses in alignment theory and practice, and equipment renting/leasing contracts. We also provide calibration services for sensors and other equipment as well as annual maintenance contracts.